The automotive industry relies heavily on advanced solutions to ensure durable and efficient vehicle assembly processes. Among these solutions, hydrophilic waterstops have emerged as a game-changer for addressing sealing challenges in vehicle manufacturing. From door seals to engine compartments, the ability of hydrophilic waterstops to expand when in contact with water has proven crucial in delivering superior waterproofing and durability. This article explores how the use of hydrophilic waterstops, including specific types like PVC and bentonite waterstops, addresses common challenges in vehicle assembly and enhances operational efficiency. Learn how PVC waterstop manufacturers play a crucial role in providing effective solutions.

Table of contents:

How Hydrophilic Waterstops Solve Automotive Sealing Failures

PVC Waterstop vs EPDM in Car Door Applications

Bentonite Waterstop Solutions for Engine Compartment Sealing

Waterproofing and sealing are essential in vehicle assembly to maintain structural integrity and passenger comfort. Hydrophilic waterstops, which expand when exposed to moisture, offer an effective solution for water ingress. They swell on contact with water, creating a tight seal against leaks. This is especially useful in high-moisture areas like door assemblies and window frames, where traditional seals often fail. Water intrusion can lead to rust, electrical damage, and poor insulation, making reliable sealing critical for automotive manufacturers.Hydrophilic waterstops, therefore, play a vital role in mitigating these problems by creating an adaptive and long-lasting barrier. These waterstops are equipped with excellent memory, allowing them to adapt to varying water levels and temperatures without losing their effectiveness. Their ability to form continuous seals even in complex shapes and joints makes them ideal for automotive applications. Leading swelling waterstop manufacturers tailor their products specifically for the precision required in vehicle design and assembly. By incorporating hydrophilic waterstops into the manufacturing process, automotive brands can enhance the durability and performance of their vehicles, ensuring better protection against environmental factors that might compromise safety and functionality.

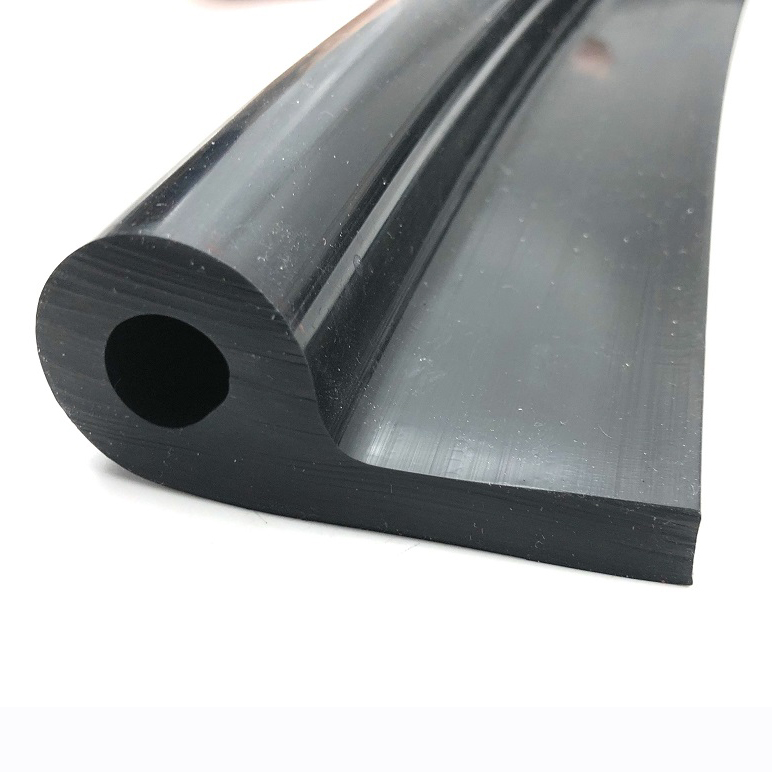

Car door assemblies are among the most exposed parts of a vehicle, constantly subjected to varying weather conditions, dirt, and water.PVC waterstops are highly durable, offering excellent resistance to chemicals, UV exposure, and extreme weather conditions, which makes them a popular choice among automotive manufacturers. PVC waterstops are especially valued for their ability to maintain flexibility and provide effective sealing over extended periods, ensuring reliability in critical areas such as door seals.On the other hand, EPDM waterstops, known for their exceptional elasticity and ability to withstand high temperatures, are often used in dynamic sections of a vehicle, like doors that require frequent motion. While EPDM can match PVC in weather resistance, the two materials serve different purposes. PVC is preferred for static applications in harsh environments, while EPDM is valued for its resilience in moving parts. Many PVC waterstop manufacturers now meet automotive standards, enabling easy integration into vehicle assembly lines. Manufacturers should evaluate their vehicle requirements to choose the right material and ensure optimal sealing performance.

The engine compartment is an area of the vehicle exposed to high temperatures, vibration, and potential fluid leaks. Proper sealing here is critical not only for preventing water ingress but also for protecting sensitive components from dust, oil, and other contaminants. Bentonite waterstops have become an innovative solution for addressing sealing challenges in engine compartments. Made from natural clay that expands significantly when exposed to moisture, bentonite waterstops create a robust barrier against water and contaminants. Their ability to seal tightly even in irregular surfaces or joints makes them ideal for complex automotive components.One of the advantages of bentonite waterstops over other materials is their ability to self-heal minor damage. If minor cracks or splits occur, exposure to moisture enables the bentonite to expand and fill the gaps automatically, ensuring continuous sealing performance. This self-healing quality is ideal for high-performance vehicles or areas with limited maintenance access. Automotive manufacturers are adopting bentonite waterstops to boost reliability and cut long-term maintenance costs. Its eco-friendly nature also makes bentonite a great choice for manufacturers aiming to meet sustainability goals while enhancing vehicle quality.

Bentonite waterstops represent a remarkable advancement in sealing technology, offering superior performance, durability, and environmental benefits. Their self-healing properties and ability to adapt to various applications make them an ideal solution for industries striving for efficiency and sustainability. By incorporating bentonite waterstops, manufacturers can achieve higher reliability, reduce long-term costs, and contribute to a greener future. This innovative material continues to set a new standard in modern engineering.

Office 301,261 Yuanhe Road,Xiangcheng District,Suzhou,Jiangsu,China

215131

Tel: (86)139 1458 5556

Email: Jimmy@arisonsltd.com